Find the Right Fit with Our Doctor Blade Products

From the People Who Made Doctor Blade Technology a Science

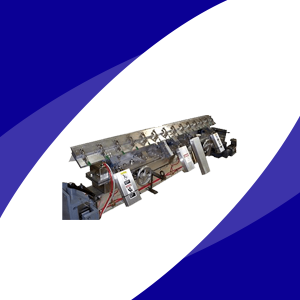

When it comes to large-scale commercial printing, few parts are as essential as the doctor blade. This part is so important because two printing methods—rotogravure (commonly known as gravure) and flexographic (widely known as flexo)—use doctor blades to control the amount of liquid ink that remains on a printing cylinder.

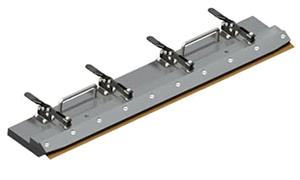

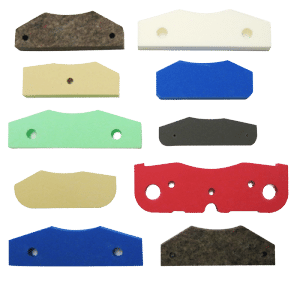

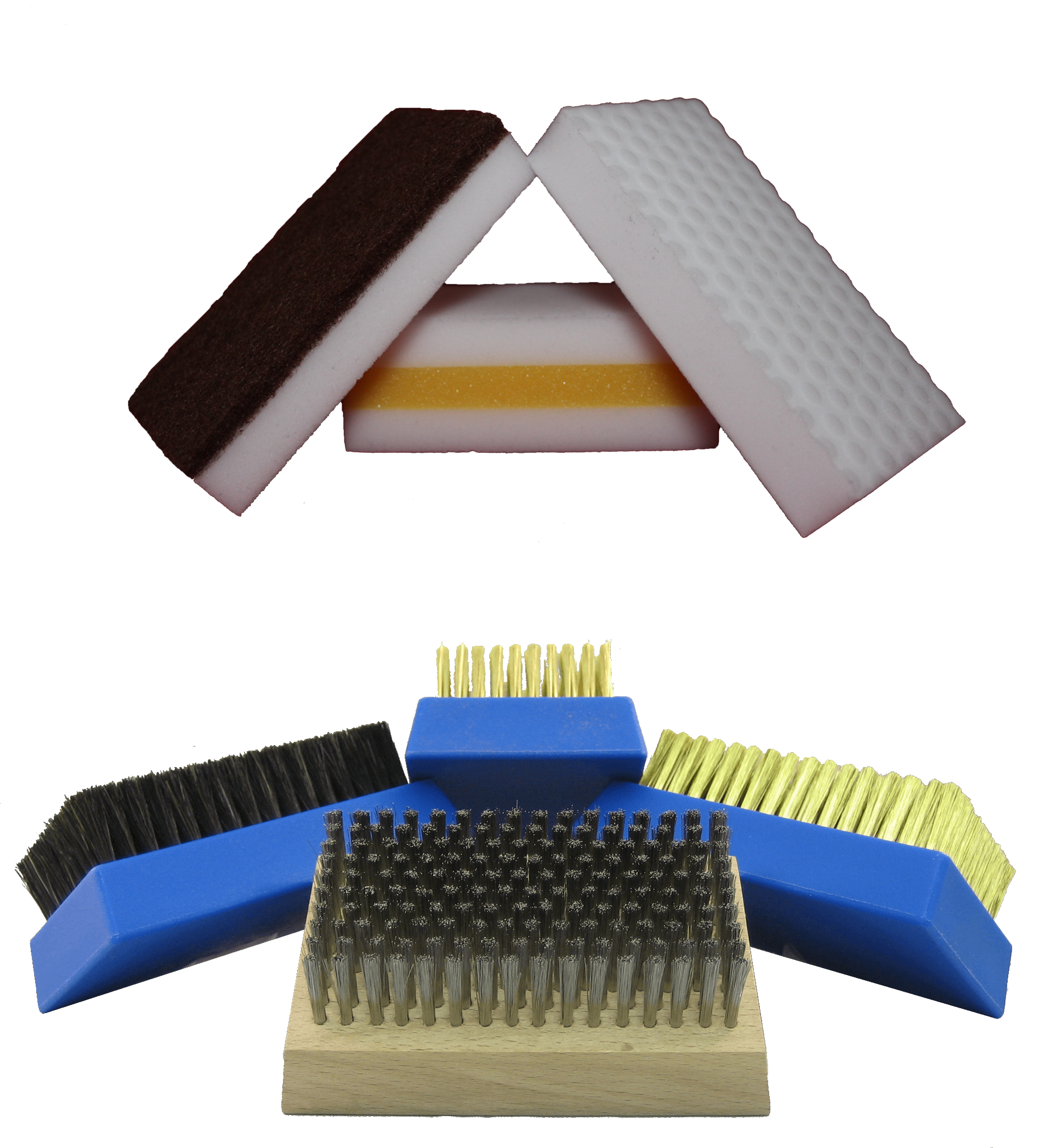

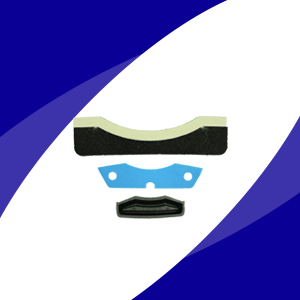

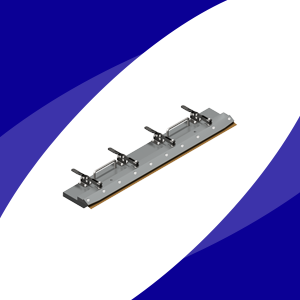

Find the correct type of doctor blade to fit your needs by turning to the professionals at Allison Systems Corporation. All of our blade materials, press cleaners, end seals for flexo printing, and edge shapes are specifically engineered for use in high-performance presses. Meet your production standards by taking advantage of our full range of printing press products.

The Right Blade for the Job

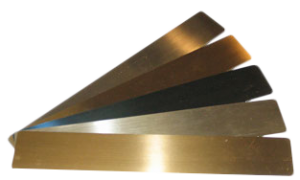

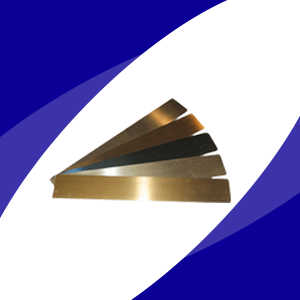

Allison Systems typically uses steel as our blade material of choice to create high-quality, repeatable doctoring results. That doesn’t mean it is our only option, however. We also offer plastic and composite blade options for gravure and flexo printing and coating applications.

No matter what type of doctor blade you need, you can rest easy knowing that our specialty blades will deliver cost-effective performance and—when properly used—can offer a longer life at high speeds when compared to other materials. Contact us today for assistance with blade selection or diagnostics services.

Allison Systems Corporation

An ISO 9001:2015 Registered Company

Allison Systems has been approved for ISO 9001:2015 Certification by Perry Johnson Registrars.

ISO 9001:2015 Quality Policy

Allison Systems Corporation is committed to achieving customer satisfaction by providing products that consistently meet or exceed customer expectations. This level of Quality is achieved by continuously improving the effectiveness of the Quality Management System.

Covid-19 Information

Allison Systems Corporation continues to monitor the Covid-19 situation, and how it may impact customers. For the most up-to-date information click here.